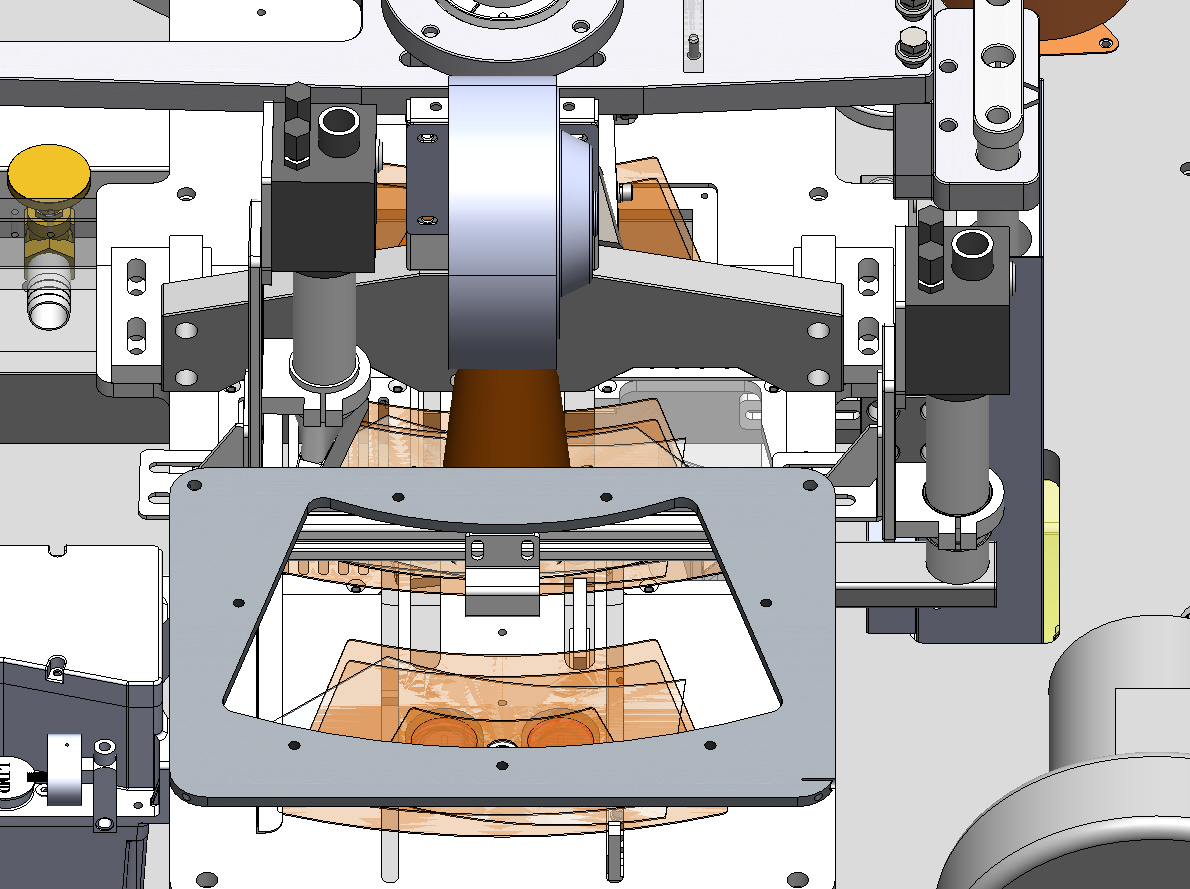

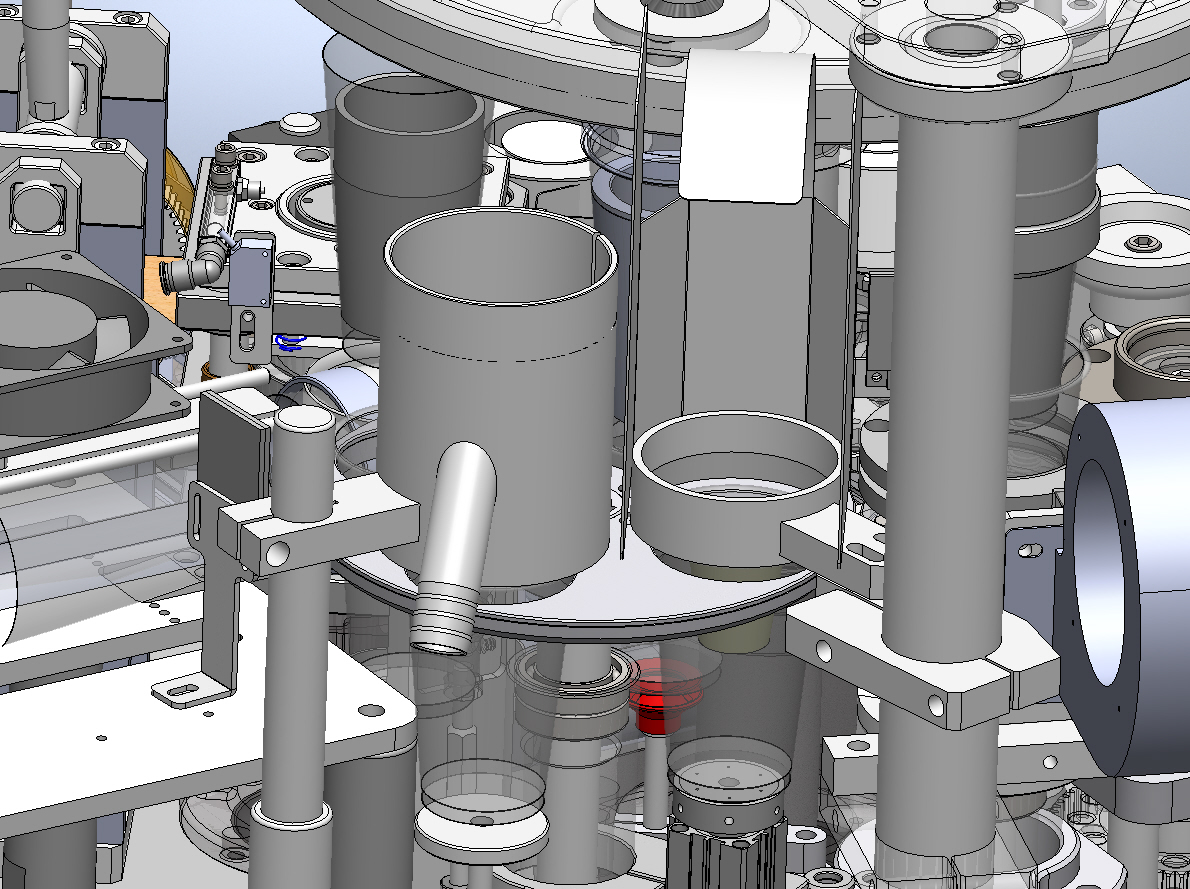

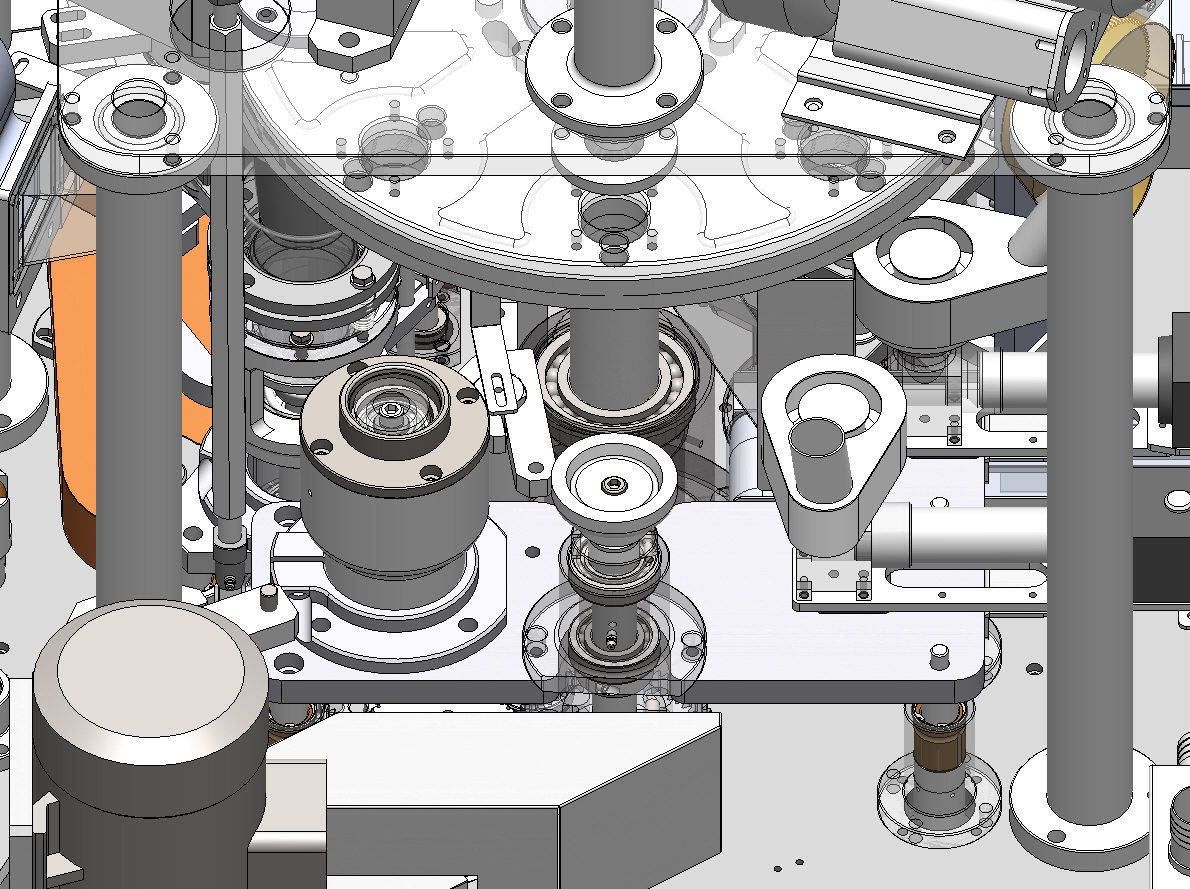

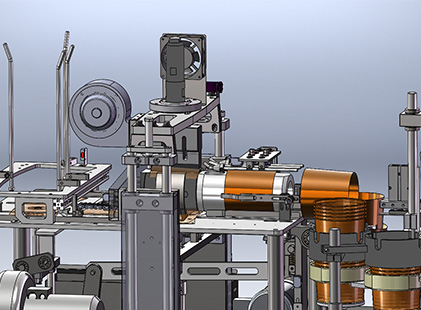

Our XC-150 represents the evolution of paper cup manufacturing technology - an upgraded model featuring our proprietary double plate forming system. Engineered for high-volume production environments, this machine delivers consistent 120-150 pieces per minute output (covering 2.5-16oz sizes) while maintaining operational stability.

|

Model |

XC-150 |

|

Machine Weight |

2900KG |

|

Wooden case dimension |

2300*1450*2050mm (L*W*H) |

|

Rated power |

Three-phase,380V,18KW |

|

Compressed air |

0.6-0.8MPa,0.4m³/min |

|

Capacity |

120-150pcs/min(2.5-16OZ) |

|

Paper materials |

Single PE/double PE |

|

Paper grammage |

150-350g/m² |

|

Product range |

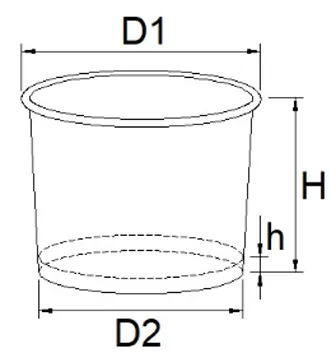

(D1)φ50-90mm (H)45-135mm |

|

|

(D2)φ36-60mm (h)4.5-10mm |