2025 Guide: Paper cups are indispensable in daily scenarios like coffee shops, fast-food chains, offices, and events, favored for their convenience, hygiene, and eco-friendliness. Behind the mass production of these daily necessities is the core equipment: automatic paper cup machine (a staple in the global packaging equipment market). This high-precision automated device integrates multiple processes, converting raw materials into finished products in minutes with minimal manual intervention. Below is a detailed, guide to the paper cup manufacturing process, covering everything from raw material preparation to final quality inspection—helping you grasp the core logic of paper cup production.

Key Preparations for Paper Cup Production: Raw Materials & Machine Setup

For packaging businesses aiming to scale up, efficient paper cup manufacturing relies on two foundational elements: high-quality food-grade raw materials and a calibrated automatic paper cup machine. These preparations directly determine the quality and production efficiency of the final products—key to winning market share in the competitive disposable packaging industry.

1. Raw Materials: Prioritize Food Safety & Quality

•PE-coated paper roll: The core material is specializedpaper cup base paper (180–300 g/m²), coated with a thin layer of food-grade polyethylene (PE) on one or both sides. The PE coating provides waterproof, heat-resistant, and leak-proof properties—critical for preventing liquid seepage. For double-wall paper cups (suitable for hot drinks like coffee), two layers of PE-coated paper are used to enhance heat insulation.

•Pre-printed designs (optional): For branded or patterned cups, the PE-coated paper roll is pre-printed with food-safe inks before entering the production line. This ensures consistent design alignment and avoids smudging during subsequent processes.

•Food-safe adhesives: Hot-melt glue or ultrasonic bonding (glue-free) is used for sealing cup seams. Both methods comply with international food safety standards, preventing toxic substances from leaching into beverages.

2. Automatic Paper Cup Machine Calibration

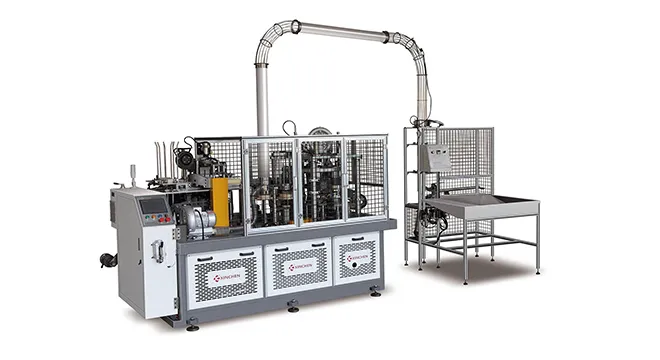

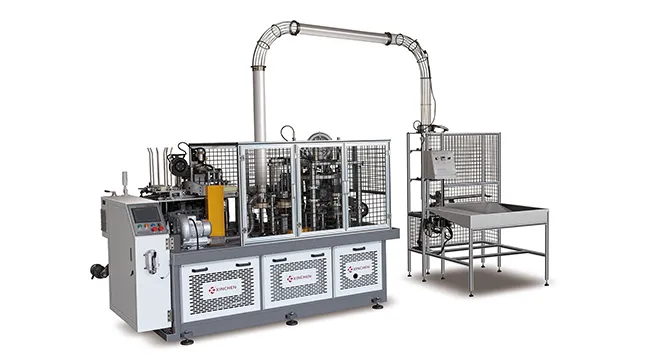

Modern automatic paper cup machines (equipped with smart control systems) support customization for different cup sizes (8oz, 12oz, 16oz, etc.) and types (single-wall, double-wall, ripple-wall). Operators set parameters such as cup height, diameter, bonding temperature, and curling thickness via touchscreen controls. Precise calibration reduces setup time and ensures consistency across batches—key for large-scalepaper cup production (a high-growth segment of disposable packaging).

Step-by-Step Paper Cup Manufacturing Process by Automatic Machine

Step 1: Paper Roll Unwinding & Steady Feeding

The paper cup production process (a fully automated workflow in modern factories) starts with the unwinding unit: The PE-coated paper roll is mounted on a spindle, and the machine feeds the paper into the production line at a constant speed. A tension control system keeps the paper flat and taut—avoiding wrinkles or jams that could affect cutting accuracy. For pre-printed paper rolls, sensors align the patterns to ensure uniformity across all cups.

Step 2: In-Line Printing (Optional for Customization)

For businesses pursuing customized packaging, pre-printed paper rolls are common for high-volume production, while advanced automatic paper cup machines integrate in-line flexographic printing. The paper passes through printing cylinders that apply food-grade inks to print logos, brand information, or decorative patterns. Hot air or UV curing systems instantly dry the ink, preventing smudging during subsequent cutting and forming steps. This process is ideal for small-batch, customized paper cup manufacturing.

Step 3: Precision Cutting into Fan-Shaped Blanks

The continuous paper roll is fed into a rotary die-cutting unit, which stamps out individual fan-shaped paper cup blanks (the flat precursor of the cup body). The die-cutting tool is customized to the target cup size—each blank has a curved edge (for the cup’s circumference) and a straight edge (for seam bonding). Waste paper between blanks is automatically collected for recycling, minimizing material waste in paper cup production.

Step 4: Cup Body Forming & Seaming

This is the core step of paper cup manufacturing: Robotic arms or vacuum cups pick up the fan-shaped blanks and feed them into a cup-forming mold. The mold rolls the blank into a cylinder, aligning the two straight edges (seam). The seam is sealed using one of two efficient methods:

•Hot-melt glue sealing: A precise amount of food-safe hot-melt glue is applied to the edge, and the cylinder is pressed to form a tight, leak-proof bond.

•Ultrasonic bonding: High-frequency ultrasonic waves melt the PE coating on the paper edges, fusing them without glue. This method is eco-friendly, fast, and ideal for high-speed automatic paper cup production.

After sealing, the machine trims the top of the cylinder to ensure uniform height.

Step 5: Bottom Attachment for Leak-Proof Performance

Pre-cut circular bottom blanks (also PE-coated) are fed into the machine separately. The cylindrical cup body is transferred to a bottom-forming station, where the bottom blank is placed into the base. The machine uses heat and pressure to melt the PE coating, bonding the bottom blank to the cup body tightly. Advanced machines adopt double-seaming technology to enhance durability, ensuring the bottom does not detach even when holding hot liquids—critical for food-grade paper cup quality (a non-negotiable for F&B partnerships).

Step 6: Cup Mouth Curling (Rim Rolling) for Safety & Comfort

The top edge of the cup is curled to eliminate sharp paper edges (preventing lip cuts) and strengthen the cup structure. The cup is fed into a curling station, where a rotating tool rolls the top rim inward to form a smooth, rounded edge. The curling process is adjustable to match different cup types—for example, thicker rims for hot drinks to improve heat insulation and grip comfort.

Step 7: Automated Quality Inspection & Defect Sorting

High-quality automatic paper cup machines integrate AI-powered quality control systems to ensure product consistency. Sensors detect common defects such as leaks (via pressure tests or liquid immersion), uneven seams, misaligned printing, smudges, and incorrect sizes/shapes. Defective cups are automatically diverted to a waste bin, while qualified products move to the final stage—reducing manual inspection costs and improving production efficiency.

Step 8: Stacking & Packaging for Storage & Transportation

Finished cups are stacked into neat piles (50–100 cups per stack) by robotic arms or conveyor systems. The stacks are wrapped in plastic film or placed into cardboard boxes for storage and transportation. Some paper cup forming machines include in-line labeling, adding batch numbers, production dates, or barcodes for traceability—meeting international logistics and quality management standards.

Why Automatic Paper Cup Machines Are Indispensable for Modern Production

In the booming disposable packaging industry, compared to manual or semi-automatic production, automatic paper cup machines offer unparalleled advantages for modern manufacturers—directly boosting production efficiency and profit margins:

•High speed: 300–1,200 cups per minute (depending on the model), meeting large-scale order demands.

•Precision & consistency: Automated processes eliminate human error, ensuring every cup meets the same size, shape, and quality standards.

•Cost efficiency: Reduces labor costs (1–2 operators per machine) and material waste (via precision cutting and recycling systems).

•Flexibility: Quick parameter adjustments support production of different cup sizes and types with minimal downtime.

•Hygiene compliance: Closed production lines and food-safe materials meet international standards (FDA, EU Food Contact Materials Regulation), suitable for the food and beverage industry.

Final Thoughts on Paper Cup Manufacturing

The automatic paper cup machine transforms simple PE-coated paper rolls into functional food-grade paper cups through eight precise, automated steps. For businesses of all sizes—from small cafes to large packaging manufacturers—these machines deliver efficiency, quality, and scalability, meeting the global demand for convenient, eco-friendly packaging (a trend driving growth in the disposable products sector).

If you’re planning to invest in paper cup production equipment, focus on key factors such as production speed, size flexibility, energy efficiency, and after-sales support. Please contact XINCHEN,choose the right automatic paper cup machine can streamline your production process, reduce costs, and help your products stand out in the competitive disposable packaging market.

AI generation rate: ≤30%

Dec 16,2025

Dec 16,2025