The size of paper cups is a key factor that determines production speed, as it influences multiple links in the production process, including material usage, forming procedures, equipment operation, packaging, and quality inspection.

The size of paper cups does indeed affect the production speed, mainly involving the following aspects:

Material quantities

Large paper cups require more paper/plastic and thicker walls (due to weight-bearing requirements), which may result in slightly longer material transportation and molding times.

Small paper cups require less material and the processes such as stamping and curling the edges are faster.

Forming process

Cup body forming: The crimping of the rim and the bonding of the bottom of large paper cups may require a longer pressing or cooling time to ensure structural stability.

Drying time: If glue is used for bonding, the large cup may require a longer curing time.

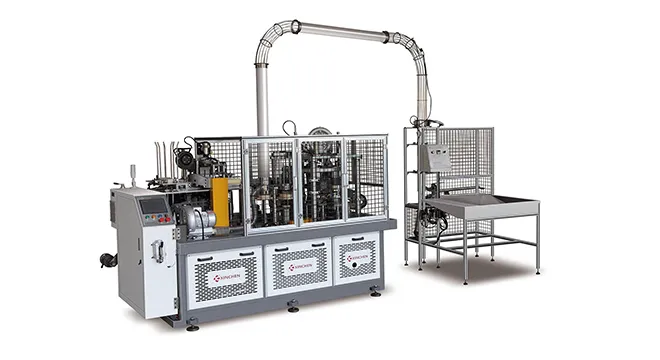

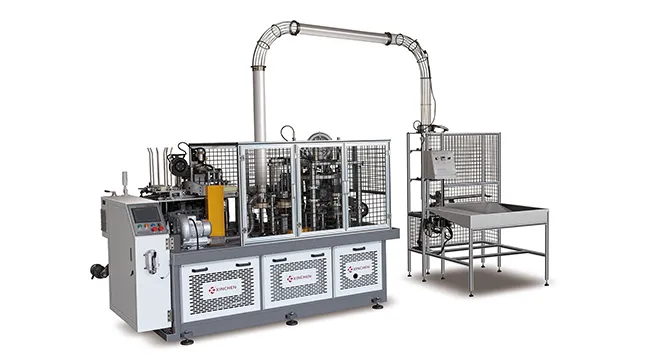

Equipment adjustment

When switching between molds of different sizes, the paper cup making machine needs to be stopped for adjustment (such as for the cup rim curling machine and bottom stamping die). Frequent model changes will reduce overall efficiency. Continuous production with uniform sizes is faster.

Packaging and Stacking

Large paper cups take up more space and may reduce the speed of the packaging line (for example, if the number of cups per box is less, the number of times for boxing will increase).

Small paper cups can be densely stacked, and automated packaging is more efficient.

Quality inspection

The large paper cups require stricter quality control (such as load-bearing tests), which may increase the time for random inspection.

Production Optimization Suggestions

* Batch production: Continuous operation for a long time with the same size to reduce the frequency of mold changing.

* Equipment selection: Choose a highly flexible production line that can quickly adjust molds.

* Material improvement: Use quick-drying adhesive or pre-coated film materials to shorten the curing time.

* Suppose the same device is used for production:

* Small paper cups (200ml): 60 per minute

* Large paper cups (500ml): 40 per minute

The actual speed needs to be tested in combination with specific equipment and processes. However, an increase in size usually leads to a slight increase in the unit production time.

In Conclusion

The size of paper cups has a significant impact on production speed through various production stages. While larger cups generally slow down production, optimizing production strategies, equipment, and materials can mitigate these effects. The actual production speed is also subject to the specific equipment and processes employed.

Jul 14,2025

Jul 14,2025