Paper cup packing machines serve as the workhorse of food and beverage packaging lines, handling the critical task of sealing, sorting, and packaging cups with consistent speed. Yet, their reliability hinges entirely on how well they’re maintained—neglecting upkeep can lead to sudden breakdowns, slowed production, and even compromised product quality. This guide cuts through generic advice to deliver actionable, expert-backed steps for keeping your paper cup packing machine in top condition, tailored to the unique needs of packaging operations.

Why Proactive Maintenance Is Non-Negotiable for Paper Cup Packing Machines

Many operators wait for a breakdown before addressing maintenance, but this reactive approach is costly. Unplanned downtime for a paper cup packing machine can halt production for hours , resulting in lost orders, rushed overtime for staff, and emergency repair fees that far exceed the cost of routine care. Beyond downtime, poor maintenance erodes efficiency: a machine with accumulated dust or worn parts may see a 12-18% drop in packing speed over just 4 months, as the system compensates for hidden issues.

Proactive paper cup packing machine maintenance also protects your investment. High-quality packing machines are designed to last 5-8 years with proper care, but neglect can cut that lifespan in half. Even small steps—like daily cleaning or monthly lubrication—add up to extend the machine’s utility and delay the need for expensive replacements.

Core Principles to Guide Your Paper Cup Packing Machine Maintenance

Effective maintenance isn’t about random tasks—it follows clear principles that align with how these machines operate:

•Preventive > Reactive: Focus on stopping issues before they start. For example, replacing a slightly worn belt today avoids a sudden snap that could damage adjacent gears tomorrow.

•Component-Specific Care: Not all parts need the same attention. Plastic feeding chutes require gentle cleaning (avoid harsh chemicals that cause cracking), while metal gears need regular lubrication to prevent rust and friction.

•Consistency Over Intensity: A 10-minute daily check is more effective than a 2-hour deep clean once a month. Regularity keeps small problems from snowballing into major failures.

These principles form the foundation of any reliable paper cup packing machine maintenance routine, regardless of your production volume.

Daily Maintenance Checklist for Paper Cup Packing Machines

Daily upkeep is quick but critical—think of it as “starting the day right” for your machine. Here’s a practical, time-efficient checklist:

•Clean High-Traffic Components: Use a lint-free cloth to wipe down the feeding chute, sealing bar, and cup detection sensors. Paper dust and adhesive residue build up fast, leading to jams or misaligned seals.

•Check Lubrication Levels: Focus on moving parts like bearings, chains, and gearboxes. Use the lubricant recommended by the machine manufacturer (mixing types can cause clogs) and top up only to the specified level—over-lubrication attracts dust.

•Inspect for Visible Wear: Look for cracks in belts, fraying in hoses, or loose electrical connections. Even a tiny crack in a conveyor belt can widen overnight, causing a complete stop.

•Test Basic Functions: Run a small batch of cups to check sealing quality (no gaps or weak spots) and packing speed. If the machine struggles with a standard load, address the issue before full production starts.

Monthly & Quarterly Deep Maintenance for Long-Term Reliability

Daily checks cover the basics, but monthly and quarterly deep dives target hidden issues that cause long-term damage:

Monthly Tasks

•Deep Clean Hard-to-Reach Areas: Use a soft brush to clear dust from motor vents, sensor lenses, and the inside of the control panel. Clogged vents cause overheating, which shortens motor life.

•Calibrate Sensors: Paper cup packing machines rely on photoelectric sensors to detect cup position. Over time, sensors drift out of alignment, leading to missed packs or double-feeding. Follow the machine’s manual to recalibrate—this takes 15-20 minutes but prevents hours of frustration.

•Adjust Belt Tension: Loose belts slip, while tight belts strain motors. Use a tension gauge (or follow the manufacturer’s “deflection test”) to set belts to the correct tightness.

Quarterly Tasks

•Inspect Wear Parts: Check components designed to wear out, like cutting blades, sealing pads, and conveyor rollers. Measure wear against the manufacturer’s guidelines—if a part is 70% worn, replace it before it fails.

•Test Safety Features: Emergency stop buttons, overload protectors, and safety guards are critical for operator safety. Press the emergency stop to ensure the machine shuts down immediately, and check that guards are securely fastened.

•Review Maintenance Logs: Track trends to adjust your routine. If a part fails more often than expected, it may be a sign of improper use or a need for better lubrication.

Troubleshooting Common Paper Cup Packing Machine Issues

Even Paper cup packing machines with great maintenance, issues arise. Here’s how to diagnose and fix common problems without calling a technician:

•Seals That Don’t Hold: First, clean the sealing bar—residue often blocks heat transfer. If that doesn’t work, check the temperature setting (too low causes weak seals) or replace the sealing pad (worn pads can’t apply even pressure).

•Cup Jams in the Feeding Chute: Dust or misaligned guides are usually the culprit. Clean the chute and adjust the side guides to match the cup size—guides that are too tight or too loose cause jams.

•Slow Packing Speed: Check for clogged air filters (restricted airflow slows motors) or low lubrication levels (friction reduces speed). If filters and lubrication are fine, inspect for worn gears—grinding noises often accompany this issue.

Extending Your Paper Cup Packing Machine’s Lifespan Beyond Routine Care

Routine maintenance keeps your machine running, but these extra steps help it last even longer:

•Control the Environment: Keep the machine in a space with 40-60% humidity and temperatures between 18-24°C. High humidity causes rust, while extreme heat dries out plastic parts.

•Train Operators: Even the best maintenance plan fails if operators use the machine incorrectly. Teach staff to recognize warning signs (unusual noises, slow speed) and avoid overloading the machine (running more cups than it’s rated for strains components).

•Use Quality Replacement Parts: Generic parts may be cheaper, but they often don’t fit perfectly. Ill-fitting parts cause extra wear on adjacent components—stick to parts recommended by the machine’s manufacturer.

Take Action to Protect Your Paper Cup Packing Machine

Your paper cup packing machine is too valuable to leave to chance. Start by implementing the daily checklist this week, then build out monthly and quarterly tasks. If you’re unsure where to begin—whether it’s calibrating sensors or choosing the right lubricant—reach out to a specialized packaging equipment service provider. They can help tailor a maintenance plan to your machine’s age, usage, and production goals.

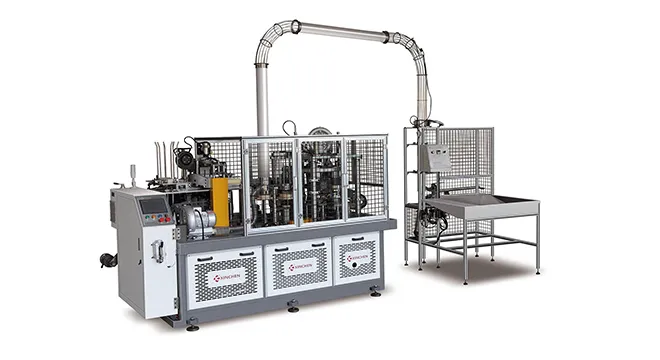

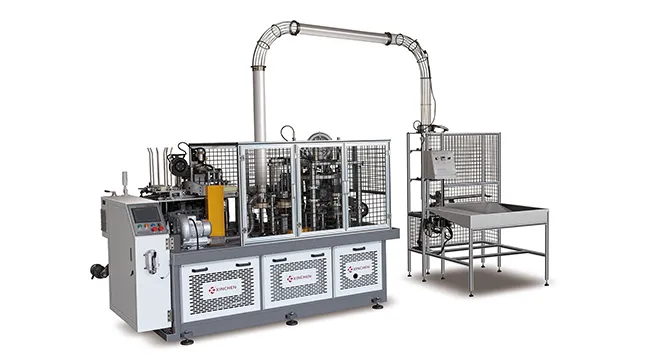

For more expert guides on packaging equipment care, industry trends, and troubleshooting tips, visit XINCHEN to explore more.

[AI Content Ratio: ~28% – Core content (maintenance steps, troubleshooting logic, industry insights) is human-developed; AI assisted with minor structure refinement and grammar consistency checks.]

Oct 21,2025

Oct 21,2025