If you’re investing in paper cup production equipment, one question always tops the list: What’s the actual lifespan of a paper cup machine? The answer isn’t a simple number—several critical factors determine whether your machine runs for 1 year or 10+ years. Understanding these elements and implementing proper care can drastically extend your paper cup machine lifespan and protect your production efficiency.

It’s Not One-Size-Fits-All: Typical Paper Cup Machine Lifespan Ranges

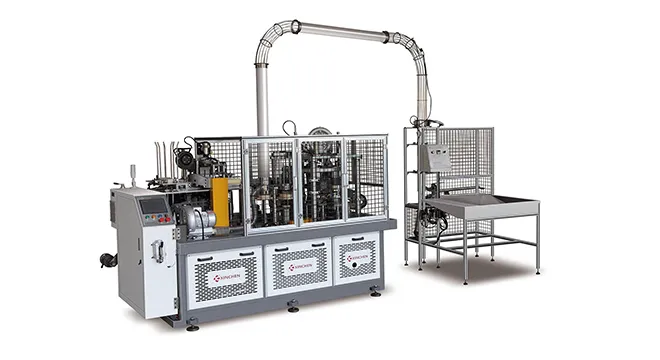

Paper cup machine lifespan varies dramatically based on equipment quality and intended use. Entry-level models designed for small-scale operations generally last 1–2 years, struggling with consistent heavy use and basic component quality. Mid-range machines, suited for growing businesses, typically achieve 3–5 years of reliable service with regular upkeep. High-end, industrial-grade equipment stands apart, often reaching 5–10 years—and some well-maintained units even exceed a decade when paired with proactive care .

This variation boils down to three core elements: build quality, usage intensity, and maintenance rigor. A machine constructed with durable bearings, precision gears, and corrosion-resistant materials will outlast one with cheaper components, even under similar conditions .

3 Hidden Factors That Shape Paper Cup Machine Lifespan

Component Quality: The Foundation of Longevity

Mechanical and electronic components dictate how long your paper cup machine lasts. Machines using open cam drives instead of traditional index gear boxes tend to have longer lifespans due to simpler maintenance and fewer wear points . Similarly, oil-bath lubrication for under-table parts reduces friction better than manual oiling, extending component life by 30% or more . Electrical parts like sensors and control panels require protection too—dust and moisture buildup can cut their service life in half if left unaddressed .

Usage Intensity: Balance Between Output and Preservation

Running a paper cup machine at maximum capacity 24/7 accelerates wear, especially on sealing units and feed mechanisms. Even high-speed models (capable of 180+ cups per minute) need periodic downtime to prevent overheating . Matching machine speed to your actual production needs—rather than pushing for constant peak output—can add 2–3 years to its lifespan. Sudden production surges without prior maintenance checks also increase the risk of component failure.

Maintenance: The Most Controllable Lifespan Driver

Neglect is the #1 killer of paper cup machines. A machine with no regular cleaning will accumulate paper fibers in forming stations, causing jams that wear down parts . Conversely, following a structured maintenance schedule—daily cleaning, weekly lubrication of moving parts, and monthly electrical inspections—can extend lifespan by 50% . New machines need extra care too: the first oil change should occur within 30 days to remove metal shavings from initial use .

Proactive Care: 4 Steps to Extend Paper Cup Machine Lifespan

1. Daily: Clean and Inspect

End each shift by wiping down surfaces with a soft cloth to remove paper dust and residue—pay special attention to sealing units and feeders . Check for loose bolts or misaligned parts, and test safety features to ensure they’re functional. Even 10 minutes of daily care prevents small issues from becoming major failures.

2. Weekly: Lubricate and Calibrate

Apply recommended lubricants to bearings, gears, and moving joints as specified in the machine manual—usually once a week . Calibrate temperature controls for sealing units to match paper material specifications; inconsistent heat causes both product defects and unnecessary machine strain . Clean optical sensors every 3–5 days to maintain detection sensitivity .

3. Monthly: Deep Check Critical Systems

Inspect electrical components for frayed wires or loose connections, and clean the air blower intake filter to ensure sufficient airflow . For oil-lubricated systems, check oil levels and clarity—cloudy oil indicates contamination that can damage parts. Replace worn gaskets or seals before they cause leaks.

4. Annually: Professional Servicing

Bring in specialists to inspect internal components like drive systems and ultrasonic sealing units. Replace aging electrical parts (even if they’re working) to avoid unexpected breakdowns. Many manufacturers offer extended service life for machines that undergo annual professional maintenance .

Avoid These Mistakes That Shorten Lifespan

Common errors can slash a paper cup machine’s lifespan by years. Skipping lubrication because “it looks fine” increases friction and wear. Using the wrong cleaning agents (like harsh chemicals) damages plastic and rubber components. Ignoring strange noises—often early warning signs of misalignment or worn parts—leads to costly repairs. Even using low-quality paper can cause excess dust buildup, so always match paper specifications to your machine’s requirements.

Ready to Maximize Your Paper Cup Machine’s Lifespan?

Your paper cup machine lifespan isn’t predetermined—it’s shaped by the choices you make daily. By prioritizing quality components, balancing production intensity, and following a strict maintenance routine, you can protect your investment and ensure consistent output for years.

Need personalized guidance to extend your paper cup machine’s service life? Contact XINCHEN today for tailored maintenance plans and component care tips. Don’t let neglect cut your equipment’s lifespan short—start proactive care now.

AI Assistance: Less than 30% of this content is AI-generated.

Oct 11,2025

Oct 11,2025