If you’ve used a paper bowl machine for a while, you may notice that the paper bowls produced sometimes have issues like uneven edges, poor sealing, or inconsistent sizes. This instability not only wastes materials but also affects production efficiency. Let’s break down the key reasons behind this problem and how to address them.

Raw Material Quality Directly Impacts Final Results

The quality of paper materials is the foundation of stable production. Even a well-functioning paper bowl machine can’t make good products with subpar paper. First, paper flatness matters—warped or wrinkled paper often leads to misalignment during forming, resulting in lopsided bowls. Second, coating consistency is critical: uneven PE or PLA coatings can cause weak sealing or leakage. Third, moisture content needs control—paper that’s too wet or too dry is hard to shape uniformly, as it either tears easily or fails to bond properly . Choosing certified, consistent raw materials eliminates most basic quality issues.

Equipment Calibration Needs Regular Checks

Many quality problems stem from overlooked calibration issues. Over time, the machine’s forming molds may shift slightly, leading to inconsistent bowl sizes . The pressure and temperature settings for sealing also require adjustment based on paper type—using the same parameters for single-layer and double-layer paper will result in either under-sealing or overheating. Additionally, the paper feeding guides need alignment: if they’re mispositioned, paper will feed crookedly, affecting the entire forming process . A monthly calibration check can resolve most of these inconsistencies.

Routine Maintenance Prevents Hidden Quality Risks

Neglecting daily maintenance is a common cause of declining product quality. Paper scraps and adhesive residue buildup in the forming area can interfere with mold movement, creating flawed bowls . Worn parts like cutting blades or sealing rollers lose precision—dull blades leave ragged edges, while worn rollers reduce sealing pressure. Even lubrication matters: insufficient lubrication causes parts to move unevenly, leading to unstable forming . Simple daily cleaning and weekly part inspections can avoid these hidden risks.

Lack of Real-Time Detection Misses Early Issues

Without real-time quality checks, small problems can escalate into large batches of defective products. A paper bowl machine without basic detection functions can’t catch issues like incomplete sealing or incorrect bottom bonding in time . Modern machines often have sensor systems that alert operators to misfeeds or mold misalignment immediately . For existing machines, adding manual spot checks every 30 minutes—focusing on sealing quality and size—helps catch errors early, reducing waste.

Summary

Unstable product quality from a paper bowl machine rarely comes from a single cause. It usually relates to raw material consistency, equipment calibration, routine maintenance, and detection measures. By addressing these four areas systematically, you can significantly improve production stability and reduce defective products.

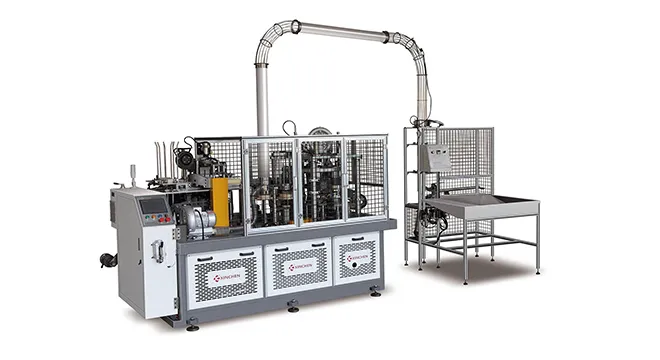

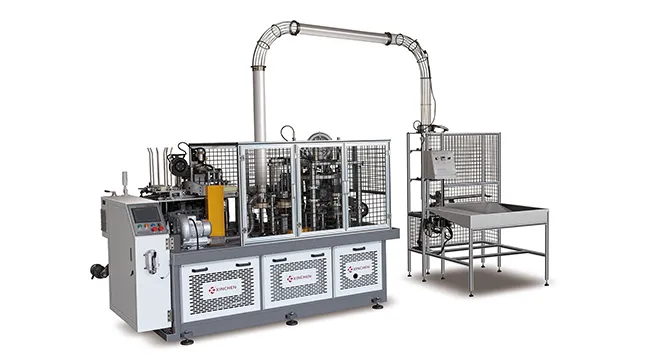

If you want to explore paper bowl machines equipped with reliable calibration systems and quality detection functions to ensure consistent output, you can visit our product page. There, you’ll find detailed information to support your pursuit of stable production quality.

Oct 08,2025

Oct 08,2025