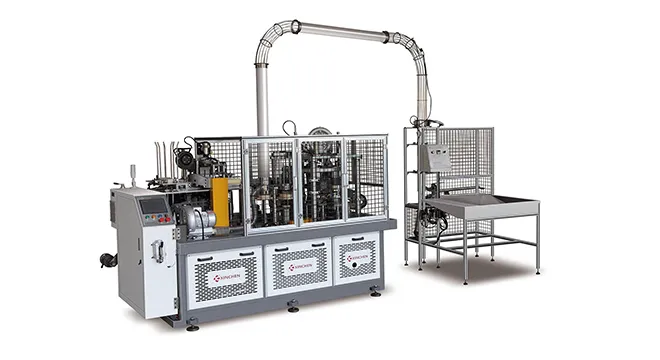

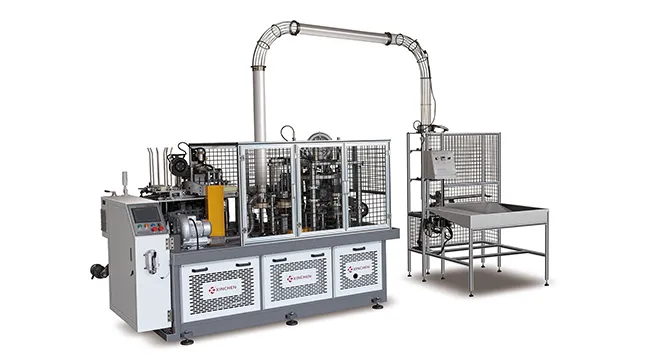

Many beginners feel confused when preparing to use a Paper Cup Machine for the first time. Overlooking key pre-operation details may lead to inefficient production or equipment issues. This article sorts out the core matters that need clarification in advance to help beginners start operations smoothly.

Understand the Cup Type Compatibility of the Equipment

Not all Paper Cup Machine models can produce all types of paper cups. First, you need to confirm the equipment’s applicable cup specifications—including the range of cup mouth diameter, cup height, and paper grammage it can handle. Different models are designed for specific product ranges; mismatched cup type requirements will directly affect forming quality. For example, machines for small coffee cups may not adapt to large-capacity beverage cups, and equipment for thin paper may struggle with thickened eco-friendly paper.

Master Pre-Operation Safety Checks

Safety is the prerequisite for operation, and two key checks must not be omitted.

Equipment State Inspection

Check whether the machine’s power supply, wiring, and connectors are intact without looseness or damage. Confirm that rotating parts like gears and conveyors operate smoothly without abnormal noise. Ensure the emergency stop button is sensitive and effective—this is crucial for handling sudden situations.

Personal Protection Preparation

Operators must wear appropriate work clothes, avoiding loose cuffs or accessories that may get caught in the machine. Do not wear gloves when touching rotating components to prevent safety hazards.

Clarify Basic Parameter Presetting Logic

Parameter setting directly impacts production results, and it should be based on two core factors. One is the paper material: thicker paper requires adjusted pressure and heating time to ensure bonding firmness, while thinner paper needs lower pressure to avoid deformation. The other is the cup size: changes in cup height and diameter require corresponding adjustments to the machine’s forming mold and conveying speed to maintain consistent product standards.

Know Post-Operation Immediate Maintenance Points

Temporary shutdown does not mean the end of work; simple maintenance can extend equipment life. After stopping production, turn off the power and clean residual paper scraps or adhesive from the mold and conveyor belt—accumulated debris will affect the next operation’s precision. Check whether lubricating parts like bearings need oiling, and ensure the machine is kept in a dry, dust-free environment.

Summary

Clarifying cup type compatibility, safety checks, parameter logic, and maintenance points before operating a Paper Cup Machine lays the foundation for efficient and safe production. These basic but critical matters help beginners avoid common mistakes and improve operational stability.

To explore reliable Paper Cup Machine options that align with these operational principles and meet your production needs, you can visit our product page for more details.

Sep 24,2025

Sep 24,2025