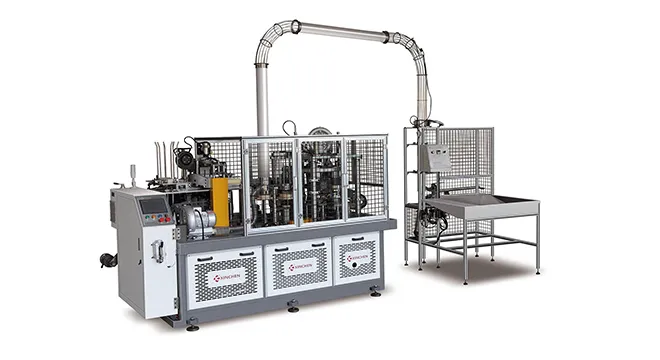

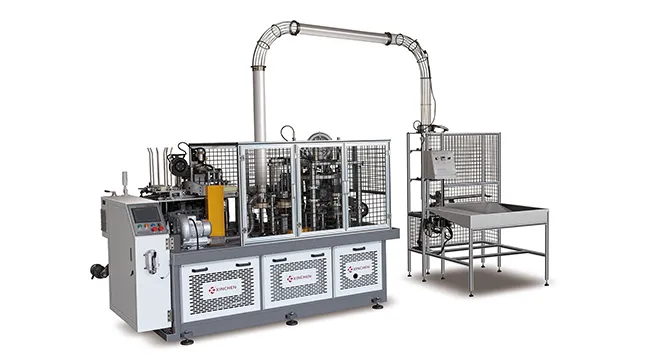

Many businesses new to paper bowl manufacturing wonder how Paper Bowl Machines handle different paper types. Paper varies in thickness, coating and size—all affecting final bowl quality—so understanding this adaptation is key to smooth production. This article breaks down the machine’s specific designs and practical steps to explain it clearly.

How Paper Bowl Machines Adapt to Different Paper Materials

1. Adjustable Pressing Components for Different Paper Thicknesses

Paper Bowl Machines use adjustable pressing components. For thick paper, turn pressure knobs to increase gentle but firm pressure to prevent cracking during shaping. For thin paper, reduce pressure to a precise light level to avoid wrinkling. This simple adjustment ensures stable bowl forming.

2. Precise Temperature Control for Single/Double PE-Coated Paper

Paper Bowl Machines have a built-in heating system with precise temperature control. For single PE-coated paper, set temperature high enough to seal the paper without melting the PE. For double PE-coated paper, use a slightly higher temperature than single PE to ensure full adhesion of its two layers. This tuning preserves waterproof function and keeps bowls intact.

3. Replaceable Molds & Adjustable Feeding for Different Paper Sizes

First, the machine has replaceable molds—swapping takes minutes. Second, the paper-feeding mechanism is adjustable: slide feeding guides to match paper width, so paper lines up perfectly with the mold. This combination lets you switch bowl sizes quickly and accurately.

How to Ensure Stable Operation When Using Different Papers

Regular Equipment Calibration

Even with good adaptive designs, parts like feeding rollers or pressing components may shift slightly over time, disrupting adaptation.

Calibrate the machine regularly: for feeding rollers, use calibration marks to set speed matching paper thickness to stop misalignment; for pressing components, check the pressure gauge and adjust back to the right level if off. This keeps adaptive functions working properly.

Pre-Production Paper Testing

Before large-batch production, confirm the machine’s settings work for your specific paper.

Run 10-20 sheets through the machine, then check two things: bowl seams (pull gently to ensure no splitting, a sign temperature/pressure is right) and bowl surface (look for smoothness, no wrinkles mean pressure is correct). If you see splits or wrinkles, adjust pressure or temperature right away—this avoids wasting paper on bad batches.

Conclusion

Paper Bowl Machines are use adjustable pressing parts for thickness, precise heating for single/double PE coatings, and replaceable molds with adjustable feeding guides for sizes. Adding regular calibration and pre-production tests ensures this adaptation works every time, helping you make high-quality bowls.

If you want to learn more about Paper Bowl Machines, or need a machine tailored to your paper types, visit our product page. There, you’ll find details on each machine’s adaptive features and how they fit your production process.

Sep 17,2025

Sep 17,2025