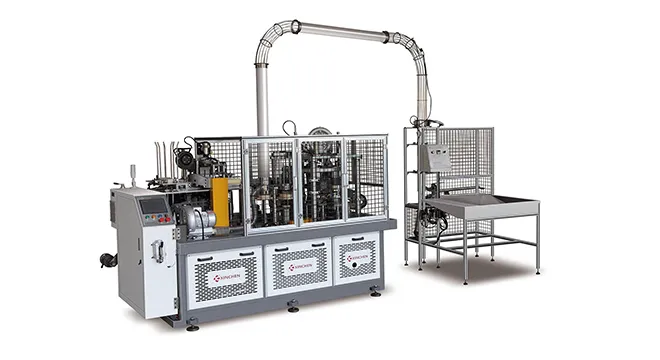

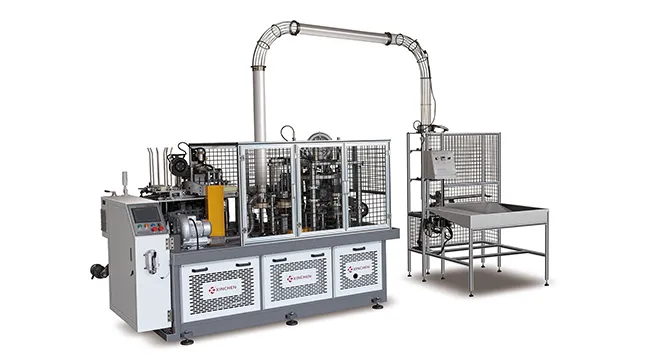

A paper bowl making machine is a specialized piece of equipment designed to automate the production of paper bowls—essential for food service, takeout, and catering businesses. Unlike manual production, this machine streamlines the process from raw paper cutting to bowl forming, ensuring consistency, speed, and cost-effectiveness. Whether for small-scale workshops or large factories, a quality paper bowl making machine adapts to diverse production needs, making it a staple for businesses focused on eco-friendly packaging.

1. What Composes a Paper Bowl Machine?

A standard paper bowl making machine relies on four core components that work together to ensure smooth, efficient production. Each component has a specific function:

•Core Transmission System: Serves as the machine’s power source, using gears and belts to synchronize all movements. It maintains stable operating speed, which reduces errors in bowl shaping and keeps product quality consistent.

•Molding Die Set: Determines the final size (e.g., 8oz, 16oz) and shape (round, square) of the paper bowls. These dies are customizable and heat-resistant, allowing long-term use without deformation.

•Intelligent Control Panel: Features buttons or a touchscreen to adjust key parameters (e.g., production speed, heating temperature). Even operators with basic training can set up and operate the machine quickly.

•Paper Feeding & Cutting Unit: Automatically feeds raw materials (usually food-safe coated paper) and cuts them into precise blanks. This unit minimizes paper waste, directly lowering production costs.

These four components form a cohesive system—without any one part, the machine’s efficiency or product quality would be compromised.

2. What Types of Bowls Can Paper Bowl Machine Make?

A versatile paper bowl making machine (especially automatic models) can produce multiple bowl types to match different market needs. Common options include:

•Disposable Food-Grade Bowls: Designed for hot foods like soups, noodles, and cereals. They use food-safe coated paper to prevent leaks and heat damage, making them ideal for restaurants and convenience stores.

•Eco-Friendly Takeout Bowls: Made from recyclable or biodegradable paper, aligning with global sustainability trends. Many cafes and food delivery platforms prioritize these bowls to reduce plastic waste.

•Custom-Printed Bowls: With an add-on printing module, the machine can create bowls with logos, brand colors, or promotional messages. This helps businesses enhance brand visibility through packaging.

•Small-Sized Snack Bowls: Used for snacks such as popcorn, fruit, or desserts. The machine easily adjusts die sizes to produce mini bowls (4oz–6oz) for convenience stores or movie theaters.

This versatility means one paper bowl making machine can serve multiple business scenarios, avoiding the need for separate equipment.

3. Why You Should Choose Paper Bowl Machines?

Investing in a paper bowl making machine offers tangible benefits for businesses of all sizes. Key advantages include:

•Eco-Friendly Alignment: Paper bowls are more sustainable than plastic alternatives, helping businesses meet consumer preferences and regulatory requirements. A paper bowl making machine lets you tap into the fast-growing "green packaging" market.

Efficiency Boost: Compared to manual production, the machine increases output by a significant margin. Even small models can produce hundreds of bowls per hour, saving time and reducing labor costs.

•Strong Versatility: One machine adapts to different bowl sizes and materials (e.g., coated paper, biodegradable paper). This flexibility is perfect for businesses with changing order demands.

•Long-Term Cost Savings: Automated production cuts down on paper waste and labor expenses. Over time, the machine’s return on investment (ROI) becomes clear—especially for high-volume producers.

[Insert Video: Demo of Automatic Paper Bowl Making Machine in Operation (From Paper Feeding to Finished Bowls)]

These advantages make the paper bowl making machine a cost-effective, future-proof investment for packaging-focused businesses.

Conclusion

A paper bowl making machine is more than basic production equipment—it’s a tool to boost efficiency, meet sustainability goals, and expand business capabilities.

For businesses seeking reliable packaging solutions, a quality paper bowl making machine is a wise investment.

Ready to find the right paper bowl making machine for your business? Contact XINCHEN today for a free consultation—we’ll help you choose a model that fits your production scale and budget!

Sep 09,2025

Sep 09,2025