Starting a paper cup production business requires careful planning of equipment, materials, and operational setup. Below is a comprehensive guide to the essentials needed to launch successfully.

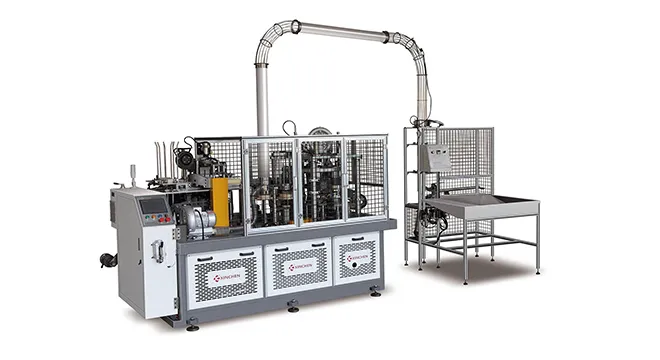

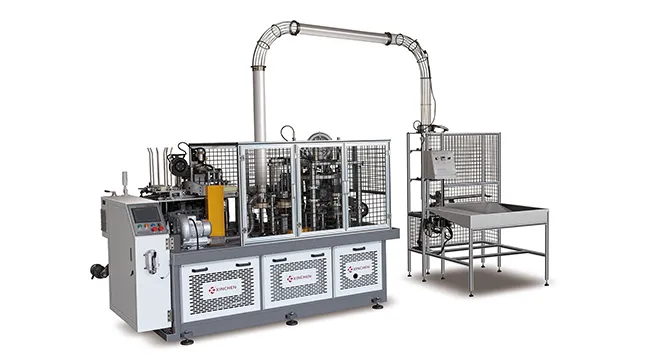

Core Production Equipment

Paper Cup Forming Machine: According to the different speeds, paper cup machines are mainly divided into slow speed and high speed paper cup machines.Generally, automatic machines handle 100-120 cups per minute, ideal for scaling.

Printing Machine: Necessary if offering customized designs. Flexographic or digital printers apply logos/patterns to paper rolls before forming, ensuring high-quality, food-safe prints.

Auxiliary Equipment

Paper Slitting Machine: Cuts large paper rolls into specified widths matching cup sizes, ensuring consistent material feed.

Packaging Machine: Automates counting and packaging, reducing manual labor and ensuring hygienic, efficient bundling.

Raw Materials

Paper Rolls: Food-grade paper (170–350 g/m²) is mandatory. Options include single-layer (for cold drinks) or multi-layer (for hot beverages).

Coating Materials: PE (polyethylene) films for waterproofing, crucial for preventing leakage in liquid-filled cups.

Operational Readiness

Staff Training: Operators should master machine calibration, troubleshooting, and quality checks to minimize defects.

Quality Control: Calipers (for paper thickness) and leakage test ensure cups meet industry standards.

By investing in the right equipment and sourcing quality materials, new entrants can establish a reliable paper cup production line. As a professional manufacturer, XinChen Machinery provides you with high-quality paper cup machine equipment to facilitate your production.

Jul 24,2025

Jul 24,2025