In the paper cup manufacturing industry, the production efficiency of a single-tray paper cup machine is directly related to the company's cost control and market competitiveness. With the continuous improvement of the industry's requirements for environmental protection, quality and production capacity, how to optimize equipment efficiency through scientific management and technological innovation has become an urgent issue for enterprises. This article cuts into the two core dimensions of raw material and process optimization, equipment maintenance and upgrading, and deeply explores the key strategies to improve the production efficiency of single-tray paper cup machines. Through refined management methods such as selecting high-toughness paper, matching high-efficiency ink glue, and optimizing hot pressing parameters, combined with equipment automation transformation and preventive maintenance system construction, enterprises can systematically break through production bottlenecks and achieve a double leap in quality and efficiency.

1. Raw materials and process optimization

①Select high-quality raw materials

Paper quality: Select paper with good quality, uniform thickness and moderate toughness as raw materials. High-quality paper is easier to transport and shape during the production process, which can reduce the occurrence of problems such as paper jams and breakages, and improve production stability and efficiency. At the same time, the grammage and specifications of the paper should match the production requirements of the equipment to avoid affecting the production speed and quality due to inappropriate paper.

Ink and glue: If the paper cup needs to be printed with patterns or pasted, reliable quality ink and glue should be selected. High-quality ink and glue have good adhesion and drying speed, which can ensure the printing and pasting effect, while reducing drying time and improving production efficiency.

②Optimize production process

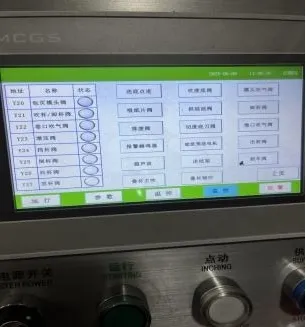

Adjust process parameters: According to the characteristics of raw materials and the performance of equipment, reasonably adjust production process parameters, such as heating temperature, pressure, speed, etc. For example, appropriately increasing the heating temperature can speed up the forming of paper, but be careful to avoid deformation of paper due to excessive temperature; adjusting the pressure can make the forming of paper cups more solid, but be careful to prevent excessive pressure from damaging the mold. Through continuous testing and adjustment, find the best combination of process parameters to improve production efficiency and product quality.

Adopt new technology: Pay attention to new technologies and new processes in the industry, and introduce new processes suitable for single-plate paper cup machines in a timely manner. For example, adopting new molding processes can shorten the molding time of paper cups and improve production efficiency; adopting environmentally friendly and efficient printing processes can reduce pollution and time consumption during the printing process.

2.Equipment maintenance and optimization

①Regular equipment maintenance

Cleaning and lubrication: Regularly clean the various parts of the single-plate paper cup machine to prevent the accumulation of paper scraps, dust and other debris from affecting the operation of the equipment. At the same time, according to the requirements of the equipment manual, lubricate key parts, such as the bearings of the turntable and the transmission chain, to ensure smooth operation of the equipment and reduce the energy loss and failure risk caused by mechanical friction, thereby ensuring the continuity and stability of production and improving production efficiency.

Check and replace wearing parts:Check the wearing parts of the equipment regularly, such as knives, molds, etc. Wear of knives will lead to unsmooth cutting, affecting the molding quality and production speed of paper cups; damage to molds may cause defective paper cups, increasing production time and costs. Find and replace worn or damaged wearing parts in time to ensure that the equipment is in good working condition.

②Equipment upgrade and transformation

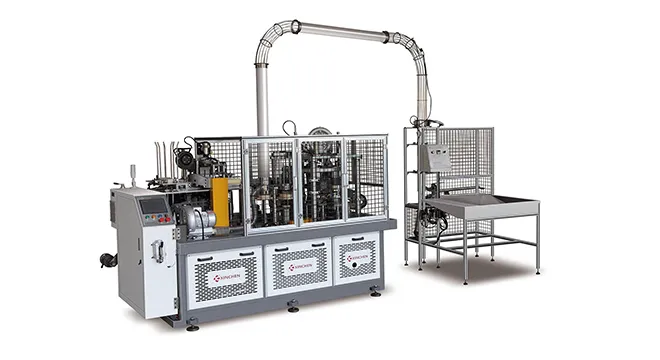

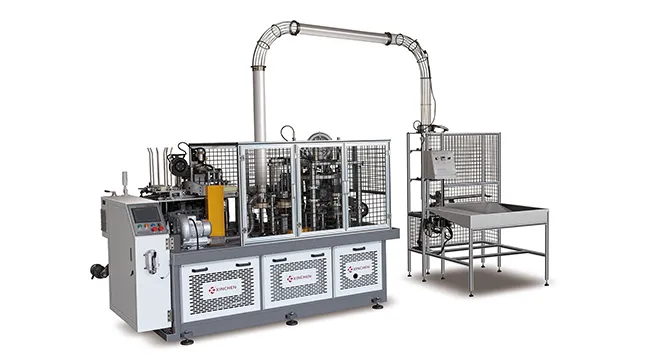

Optimize the drive system: The drive system of the single-plate paper cup machine plays a key role in production efficiency. You can consider upgrading the drive motor and choose a motor with appropriate power, stable performance and adjustable speed to improve the speed and accuracy of the turntable. At the same time, improve the transmission device, such as using more efficient chains, belts or gear drives to reduce the loss during power transmission, so that the equipment can complete each process faster and more accurately.

Install automation devices: Install automation devices on the single tray paper cup machine, such as automatic paper feeding system, automatic counting system and automatic stacking system. The automatic paper feeding system can realize fast and accurate paper delivery, reducing the time and error of manual operation; the automatic counting system can count the production quantity in real time, which is convenient for production management; the automatic stacking system can automatically stack the produced paper cups neatly, improving the efficiency of subsequent packaging.

Summary:

Improving the production efficiency of a single-tray paper cup production machine is not an improvement in a single link, but a full-link lean management that runs through raw material adaptation, process innovation, and equipment operation and maintenance. By establishing a dynamic process parameter database and introducing intelligent sensing technology to monitor equipment status in real time, enterprises can upgrade traditional experience-driven to data-driven precision control mode. In the future, with the deep integration of industrial Internet of Things technology and modular design concepts, the single-tray paper cup machine will continue to evolve towards flexibility and intelligence, providing more efficient solutions for the paper products processing industry. Only by insisting on both technological iteration and management innovation can we build a sustainable efficiency advantage in the fierce market competition.

May 27,2025

May 27,2025