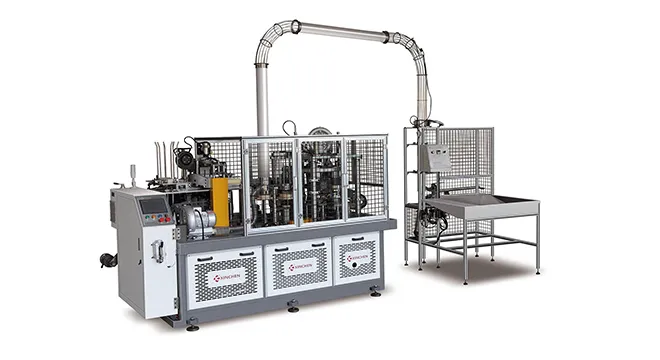

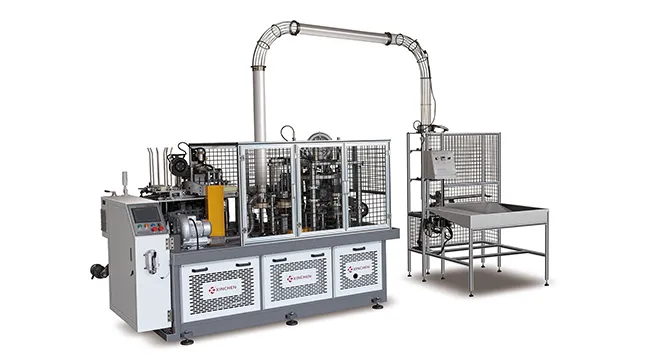

In the competitive landscape of paper cup manufacturing, the single-tray paper cup machine stands out as a game-changer for mass production, offering unparalleled advantages in cost efficiency, productivity, and quality control. By leveraging economies of scale, this technology enables manufacturers to significantly reduce per-unit costs, streamline operations, and meet large-scale market demands with consistency. This article explores four key benefits of single-tray paper cup machines in mass production: cost savings, enhanced production efficiency, superior quality management, and reliable market supply. Whether you’re a startup or an established player, understanding these advantages can help optimize your production strategy and boost profitability.

1.Cost advantage

①Reduced raw material procurement costs

In mass production, the purchase volume increases, which gives you more advantages in negotiations with raw material suppliers and allows you to obtain lower purchase prices and more favorable payment terms. For example, when purchasing large quantities of raw materials such as paper and ink, suppliers often give you a certain price discount to reduce the unit raw material procurement cost. Moreover, centralized procurement can also reduce the number of purchases and reduce transportation, manpower and other costs during the procurement process.

②Equipment and labor cost allocation

The single-tray paper cup machine requires a certain amount of time and cost during the startup and debugging phase. Mass production can allocate these fixed costs to more products. Taking equipment depreciation as an example, the purchase cost of a single-tray paper cup machine is high, but as the production volume increases, the equipment depreciation cost allocated to each paper cup will decrease. In terms of manpower, in mass production, operators can continue to work efficiently, and the labor cost per unit product will also be reduced accordingly. For example, a worker operating a single-tray paper cup machine will not spend much time on producing 1,000 paper cups or 100 paper cups, but the labor cost allocated to each paper cup will be greatly reduced in mass production.

2.Production efficiency advantage

①Reduced equipment debugging time

Single-tray paper cup machines need to be debugged when producing paper cups of different specifications or styles, including adjusting molds, setting parameters, etc. For batch production of paper cups of the same specification, only one debugging is required, which avoids the time wasted by frequent debugging of equipment and improves the utilization rate of equipment. For example, when producing a batch of 5,000 paper cups of the same specification, continuous production can be carried out after one-time debugging is completed, which can save a lot of debugging time compared to multiple small batch production of paper cups of different specifications.

②Improve operational proficiency

For operators, batch production of the same product can make them more proficient in mastering the operating procedures and skills, improving work efficiency and quality stability. As the production volume increases, operators become more familiar with the performance and operating points of the equipment, and can complete each production link more quickly and accurately, reducing the defective rate caused by operational errors, and further improving overall production efficiency.

3.Quality Control Advantages

①Stable production process

During batch production, the production process of the single-plate paper cup machine is relatively stable, and all parameters can remain consistent. Stable production process helps to ensure the consistency and stability of product quality and reduce defective products caused by process fluctuations. For example, in the process of paper cup forming, the stable control of parameters such as temperature and pressure is crucial to the quality indicators such as the shape and strength of the paper cup. Batch production is more conducive to maintaining the stability of these parameters.

②Convenient for quality monitoring

Due to the large number of products produced in batches, a more scientific sampling and testing method can be used to monitor product quality. By sampling a certain proportion of paper cups for quality testing, quality problems that may occur in the production process can be discovered in a timely manner, and corresponding measures can be taken to adjust and improve. Moreover, a large amount of production data can also help analyze the root causes of quality problems, thereby optimizing production processes and improving product quality.

4.Market supply advantage

①Meeting large-scale order demands

In the market competition, enterprises may receive large-scale orders. The mass production capacity of the single-tray paper cup machine enables it to quickly respond to these order demands, provide products on time and in quantity, and enhance the competitiveness of enterprises in the market. For example, when catering companies hold large-scale events, they need a large number of paper cups. Companies with mass production capabilities can meet their needs, thereby winning the trust of customers and long-term cooperation opportunities.

②Stable market supply

Mass production can ensure the continuous and stable supply of products and avoid the situation of market shortages due to insufficient production. Stable market supply helps companies establish a good brand image, improve customer satisfaction and consolidate market share. For some long-term cooperative customers, stable supply is an important basis for establishing a cooperative relationship.

In summary

The single-tray paper cup production machine is a powerhouse for mass production, delivering tangible benefits across cost, efficiency, quality, and supply chain stability. By minimizing raw material and labor costs, reducing downtime, ensuring consistent product quality, and enabling swift responses to bulk orders, this technology empowers manufacturers to thrive in a demanding market. As industries increasingly prioritize sustainability and scalability, investing in single-tray paper cup machines becomes not just a competitive edge but a strategic necessity. For businesses aiming to expand their footprint and meet evolving customer expectations, embracing this solution is a decisive step toward long-term success.

May 30,2025

May 30,2025