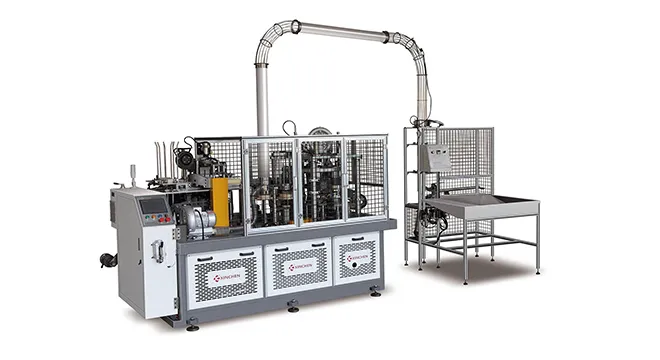

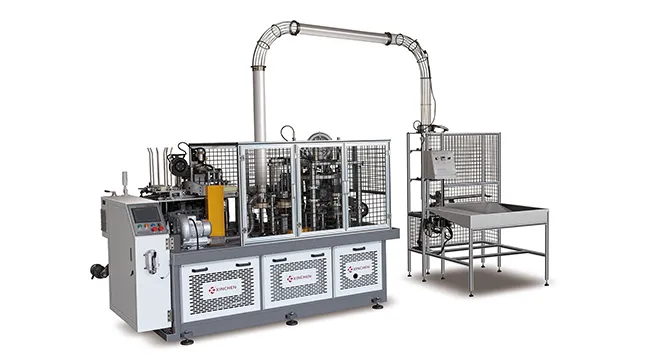

A paper cup machine is a valuable asset for businesses in the food and beverage industry. Regular maintenance is crucial to keep it running smoothly. But how exactly should you maintain it?

Why Maintain a Paper Cup Machine?

Proper maintenance ensures the machine operates efficiently, reducing downtime. Neglected paper cup making machines are 30% more likely to break down, leading to production losses. Well - maintained machines also produce higher - quality cups, enhancing your brand image.

When to Conduct Maintenance?

Prevents Downtime: Machines with irregular maintenance face a 30% higher risk of breakdowns, disrupting production schedules.

Quality Assurance: Properly calibrated machines produce uniform, defect-free cups, preserving brand reputation.

Cost Efficiency: Routine care reduces long-term repair expenses and delays caused by unexpected malfunctions.

Maintenance Schedule

* Daily:

Clean residual glue, paper scraps, and dust after each shift.

Verify alignment of feeding mechanisms and cup-forming molds.

* Weekly:

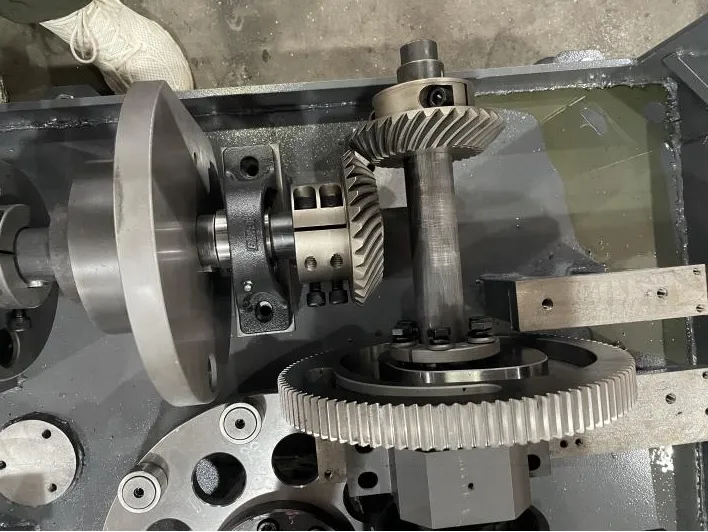

Inspect belts, chains, and bearings for wear or misalignment.

Test temperature controls on heating elements (if applicable).

* Monthly:

Examine electrical systems for loose wiring or corrosion.

Assess hydraulic/pneumatic systems for leaks or pressure inconsistencies.

How to Maintain a Paper Cup Machine?

Cleaning: Use a soft brush to clean paper debris from the paper - feeding mechanism. Cleaning reduces the risk of jams and ensures smooth operation.

Lubrication: Apply lubricant to moving parts like gears and bearings. This reduces friction, extending the lifespan of components.

Inspection: Regularly check for loose screws and worn - out parts. Tighten any loose connections immediately. Replace parts like cutting blades when they show signs of wear.

What Results Can You Expect?

Extended Lifespan: Paper cup forming machines last 20% longer with consistent upkeep.

Operational Efficiency: Breakdowns decrease by 50%, maximizing daily output.

Sustainability: Reduced material waste from misaligned or faulty production cycles.

By adhering to this maintenance protocol, businesses ensure reliable performance, minimize operational costs, and maintain consistent product quality. Schedule a professional technician annually for advanced diagnostics and calibration to further optimize machine longevity.

May 14,2025

May 14,2025