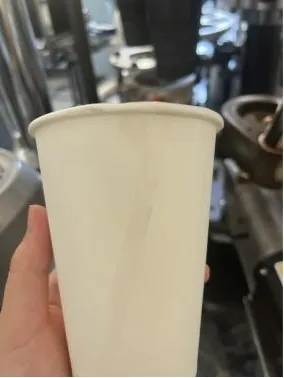

In the production process of paper cups, the curling process is one of the key links to ensure the quality and performance of paper cups. A flat and firm curl can not only improve the appearance of the paper cup but also enhance its sealing and durability. However, in actual production, various problems often occur in the curling process, affecting the quality of the paper cup. So, what are the reasons for the problems in the curling process during paper cup production?

①Paper cup material

The material used for paper cups is not thick enough or of poor quality, which can easily lead to loose curling and deformation. Poor quality paper cup materials cannot withstand the pressure and operation in the curling process, making the curling fail to achieve the expected effect, or even return to its original state after curling.

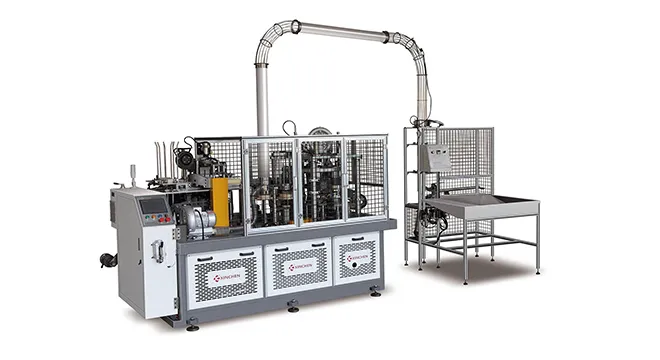

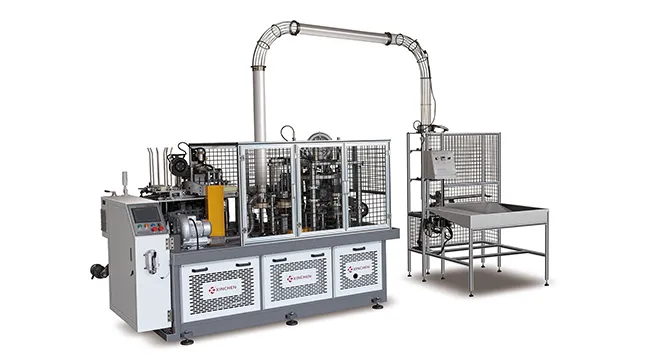

②Improper machine operation

If the operator is not proficient in the operating skills of the paper cup machine, operational errors may occur in the curling process, such as inaccurate pressure setting, improper speed adjustment, etc., which will affect the curling quality.

③Inadequate machine maintenance

Insufficient machine pressure or severe wear of machine parts will directly affect the curling process. Insufficient pressure cannot achieve the ideal curling effect on the edge of the paper cup; severe wear of parts may cause the curling shape to be irregular and uneven.

④Mold problems

If the operator does not adjust the mold correctly or the mold is damaged, it will cause problems with the curling. Improper mold adjustment may cause the size and angle of the curling to not meet the requirements; mold damage will cause defects on the curling surface, such as scratches, dents, etc.

⑤Process control issues

In the curling process, if the temperature, time and other process parameters are not properly controlled, the curling effect will also be affected. For example, too high a temperature may cause the paper cup material to deform, while too low a temperature may cause the curling to be loose.

To sum up

The problems in the curling process during paper cup production are caused by a combination of factors, including paper cup materials, the operation and maintenance of the paper cup machine, molds, and process control. Only by taking corresponding solutions to these possible causes can we effectively reduce the occurrence of curling problems, ensure the quality of paper cup production, and thus meet the market's quality requirements for paper cup products.

Jul 21,2025

Jul 21,2025