When it comes to paper fan production, the choice between double knife straight edge and single knife inclined edge cutting methods is a crucial decision that directly impacts production efficiency, product quality, cost, and applicability. Each method has its unique characteristics, and selecting the right one requires a comprehensive consideration of various factors.

How to choose between double knife straight edge and single knife inclined edge for paper fan?

①From the perspective of cutting efficiency:

Double knife straight edge: Usually, double knife straight edge can perform two cuts simultaneously, which can significantly increase the cutting efficiency in mass production scenarios. If your production demand is large and you need to cut a large number of paper cup sheets within a short period of time, double knife straight edge may be more suitable. For example, large paper cup manufacturers that need to produce tens of thousands of paper cups every day can complete the cutting task quickly using double knife straight edge, thereby improving the overall production capacity.

Single knife inclined edge: Single knife inclined edge can only perform one cut at a time, and the cutting efficiency is relatively low. However, if the production scale is small and the requirement for cutting speed is not particularly high, single knife inclined edge can also meet the basic production needs and may have an advantage in some fine-cutting processes.

②From the perspective of cutting effect:

Double knife straight edge: The edges produced by this method are relatively neat and vertical. For situations where there are high requirements for the edge of paper cups, such as making high-end paper cups or those that need further fine processing, double knife straight edge can ensure the cutting quality. The paper pieces after straight edge cutting are more closely joined, making the overall structure of the paper cup more stable.

Single knife inclined edge: The inclined edge cutting will cause the edge of the paper cup to form a certain slope. This slope may have unique advantages in some cases. For example, when making some paper cups with special appearance effects, inclined edge cutting can add a sense of three-dimensionality and beauty to the paper cup. In addition, inclined edge cutting may be easier to operate in some parts that need to be folded or bent because the inclined surface can provide certain buffering and guiding functions.

③Cost Consideration

Double knife straight edge: Due to the relatively complex structure of the double knife straight edge, the cost of the tool and maintenance costs may be higher. The design of the double-edge requires more precise manufacturing processes and materials, and during use, if one of the knives breaks, it may be necessary to replace both knives at the same time, increasing the usage cost.

Single knife inclined edge: The structure of the single inclined edge is simple, the tool cost is relatively lower, and maintenance is more convenient. For small enterprises or individual operators with limited budgets, the single inclined edge may be a more cost-effective choice.

④Applicability considerations

Double knife straight edge: This design is more suitable for cutting paper cup sheets with harder texture and uniform thickness. The straight edge cutting method can effectively cut the material and ensure the quality of the cut. However, for some materials with softer texture or uneven thickness, the double knife straight edge may experience difficulties in cutting smoothly or have uneven cutting edges.

Single knife inclined edge: This design has a stronger adaptability to materials and can cut paper cup sheets of various textures and thicknesses. When cutting materials with softer texture, the inclined edge cutting method can better avoid material deformation and tearing, ensuring the cutting effect.

In Conclusion

The choice between double knife straight edge and single knife inclined edge for paper fan cutting depends on a combination of production needs, quality requirements, budget constraints, and material characteristics. By carefully evaluating these factors, you can make an informed decision that optimizes your production process and meets the specific demands of your paper fan products. Whether prioritizing efficiency, precision, cost, or material adaptability, there is a suitable cutting method to achieve your desired outcomes.

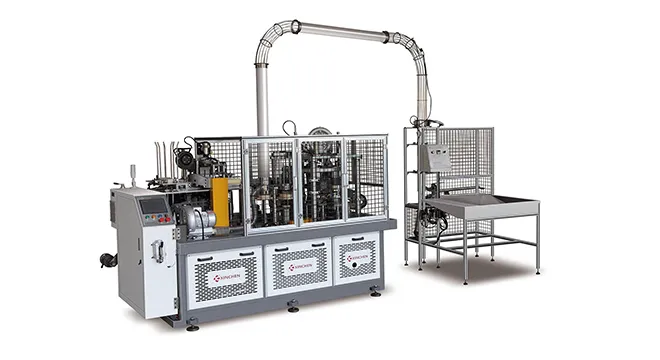

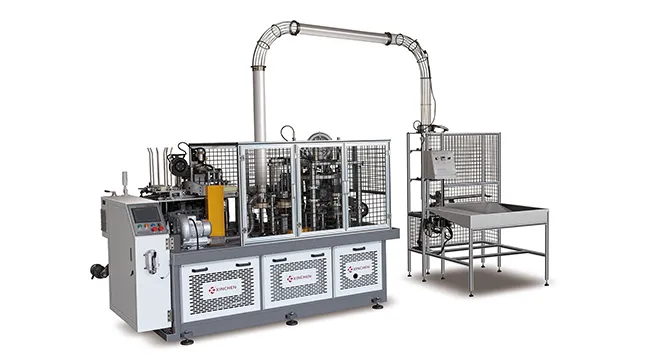

Tag: XC-150 High Speed Automatic Paper Cup Making Machine, XC-D16 Paper Cup Forming Machine

Jul 17,2025

Jul 17,2025