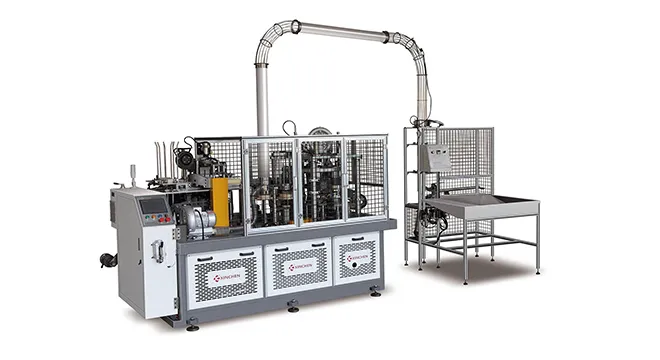

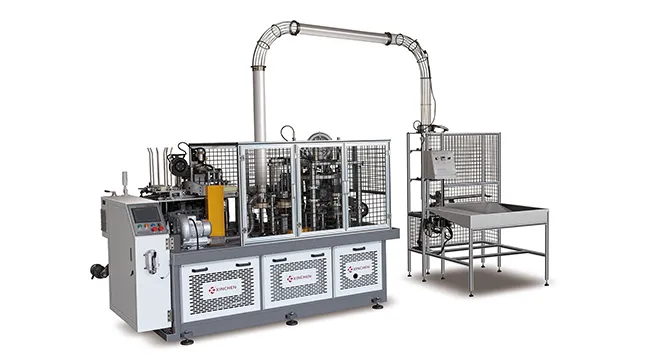

In the context of the booming beverage and food industries, the demand for disposable paper cups has been surging. To keep up with this growing need, manufacturers are constantly seeking advanced production equipment. The double-plate paper cup machine emerges as a cutting-edge solution, revolutionizing the paper cup manufacturing process with its unique design and superior performance.

1. Basic Concept

- Dual-plate design: The equipment is equipped with two separate plates (workstations), allowing for simultaneous execution of different processes (such as cup body molding and cup bottom welding). This parallel processing mode is a significant upgrade from the traditional single-plate machines, which can only handle one process at a time.

- Automation level: From paper feeding, forming, bottom punching to cup output, all processes are completed automatically, reducing the need for manual intervention. It typically adopts advanced sensors and programmable logic controllers (PLC) to ensure precise operation, with an error rate of less than 0.5%.

- Additional technical details: Most double-plate paper cup machines have a voltage requirement of 220V or 380V, and a power consumption ranging from 5kW to 10kW, depending on the model and production capacity. They also feature a user-friendly touch screen interface for easy operation and parameter adjustment.

2. Core Function

One workstation is responsible for producing the cup body, while another workstation simultaneously completes the welding of the cup bottom, thereby reducing the production time for a single cup. The coordination between the two workstations is seamless, achieved through a sophisticated synchronization system that ensures the cup body and bottom are perfectly aligned during the final assembly.

3. Advantages

- High efficiency: The dual-disc design increases production capacity by 30% to 50% compared to single-disc models. For example, if a single-disc machine produces 100 cups per minute, a double-plate one can produce 130 to 150 cups within the same time frame.

- High flexibility: Capable of quickly switching production modes and adapting to changes in orders. It can handle various cup sizes, from small 4oz cups to large 20oz cups, by simply adjusting the relevant parameters on the control panel, which usually takes less than 10 minutes.

- Energy conservation and environmental protection: Some models are equipped with a waste recycling system, reducing paper waste. Moreover, the automatic operation minimizes energy loss caused by human factors, and the use of eco-friendly lubricants in the machine parts further aligns with environmental protection standards.

In conclusion, the double-plate paper cup machine stands out as a game-changer in the paper cup manufacturing industry. Its dual-plate design, high automation level, and versatile functions contribute to higher productivity, better adaptability, and greener production. For businesses aiming to enhance their competitiveness in the market, investing in a double-plate paper cup machine is undoubtedly a wise decision that can bring long-term benefits in terms of cost savings and efficiency improvement.

Jul 16,2025

Jul 16,2025